When it comes to pipeline maintenance and protection, internal pipe coating equipment is one of the most critical aspects that can help extend the life span of pipes as well as improve their performance. This article provides a complete guide on different types of tools used for coating inner parts of pipes, methods applied during the process, and which applications are suitable for each technique. It also touches on operational principles, material considerations, and industry standards, among other things related to internal pipe coatings, so that readers can have a solid knowledge base in managing pipelines. The information shared here will be beneficial not only for those who work in industries dealing with pipelines but also for project managers or anyone interested in gaining more knowledge about these systems, since they can use them when making decisions for the successful completion of various projects that involve laying down underground utilities.

What is Internal Pipe Coating Equipment?

Understanding Pipe Coating Systems

Specialized technologies are internal pipe coating systems. These technologies aim to apply coatings that protect and improve the performance of inner surfaces in pipelines. Methods for application, materials used, and specific goals vary greatly among different types of these systems. Some common techniques are centrifuge-applied coatings, spray coating, and brush/roller applications. Such factors as the environmental conditions, type of fluid conveyed through it, or particular wear mechanisms caused by corrosion usually determine what kind should be selected. Advanced polymers like epoxy resin-based ones, which include polyurethanes, can make up such coatings themselves because they resist chemical attacks well. So far, mechanical abrasion resistance also plays an important role here. In different industries where efficiency matters most, while keeping up integrity requires us to understand them deeply

Types of Internal Pipe Coating Machines

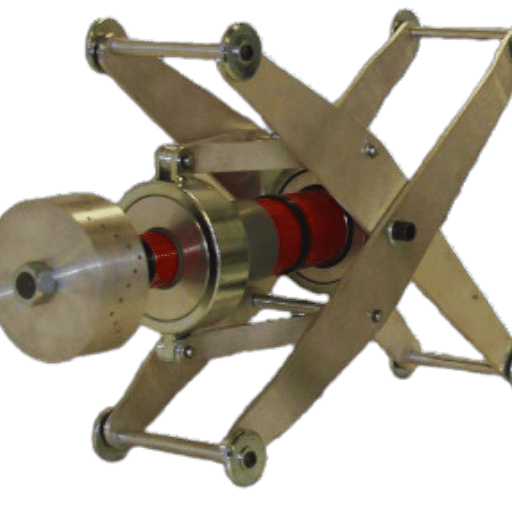

Depending on their application techniques and functionality, machines for internal pipe coating can be divided into different types. Various systems are classified as the main types, such as centrifugal coating systems and Graco technology, among others.

- Spray Coating Machines: These machines use high-pressure sprayers to coat pipeline interiors uniformly. They are suitable for complex geometries and give a consistent thickness.

- Centrifugal Coating Systems: In this case, coatings are applied by spinning the pipe and distributing material evenly around the inner surface using centrifugal force. It is good for getting thick layers that last long.

- Brush or Roller Application Machines: These machines apply coatings manually or automatically with brushes or rollers. They are used mostly with small diameter pipes where the accuracy of application matters most.

- Injection Coating Systems: Here, the pumps are used to directly inject the coating into the pipeline, thus ensuring thorough coverage even in the imperfect parts of its surface.

Each machine type is chosen depending on particular project needs, like size & shape of pipes involved, type of coating materials being used, as well as desired efficiency in the application process. Therefore, one should know what each machine does uniquely to maintain pipelines effectively while improving their performance too.

How Internal Pipe Coating Equipment Works

A systematic process of internal pipe coating equipment is implemented to ensure the best possible application of the materials used for coating in a pipe with consideration of its i.d. Initially, this machine cleans off any dirt, rust, or other impurities that may be present on inner surfaces, thereby making coatings stick better. The equipment does this by cleaning up first. Then, it applies its coat through spraying, centrifugal force, brushing, rolling, or injection methods, which are selected according to a particular project, such as painting tubes inside. It might also cure or dry after finishing the application, while hardening this layer to enhance its protective properties. All these activities increase durability and life expectancy and save money spent on repairs and operational shutdowns due to maintenance work. To optimize the efficiency of both the equipment and pipeline coatings, one should understand how they work.

How to Choose the Right Pipe Coating System?

Factors to Consider When Selecting Coating Equipment

While picking the appropriate interior pipe coating equipment, there is a list of some important things that should be taken into consideration:

- Pipe Specifications: This involves checking the diameter, length, and wall thickness of pipes to ensure that they are compatible with the coating equipment.

- Coating Material: Types of coatings, such as epoxy, polyurethane, or polyurea, may need different application methods and equipment settings to achieve the best results.

- Project Scope and Scale: The size and complexity of a project will determine whether an advanced automated system is required for larger operations or if a smaller manual rig can do just fine.

- Environmental Conditions: The operational environment, including temperature levels and humidity rates, could affect both performance on coatings themselves as well as their corresponding equipment’s performance; hence,e it is advisable to select those systems which can operate effectively under expected environmental conditions.

- Efficiency and Application Speed: How fast you want to apply it, plus how efficient the whole process will be, should be put into consideration since this will reduce idling time during other projects’ completions, which may require similar services within the same period, thus saving on time too.

- Costs and Budgeting: One should also consider the initial capital investment needed versus ongoing operation costs while ensuring that all these align with the overall financial plan for such an undertaking, taking cognizance of future savings through regular maintenance activities, among other things.

By carefully considering these factors, engineers and managers can select interior pipe coating equipment that meets technical requirements and enhances general success within any given venture.

Comparing Different Pipe Coating Systems

When rating tube coatings, it is vital to compare different types of technologies concerning certain performance indicators like strength, method of application, and environmental friendliness.

- Epoxy Coatings: These are widely known for resisting chemicals and moisture, thus can be used on both internal and external parts of a pipe. Typically, they have strong adhesion properties, which offer protection against corrosion, although it may require a more complex process during their application, where surfaces must be thoroughly prepared before being coated using a gun.

- Polyurethane Coatings: These coatings can flex easily without breaking while still being impact resistant; this makes them ideal for industries where pipes may frequently undergo temperature changes or mechanical stresses. They also exhibit good resistance to UV light, so they work well for outdoor applications. However, they are costlier than other options, so a skilled applicator is needed to guarantee the desired outcome.

- Polyurea Coatings: This option dries quickly, thus becoming very tough; it can withstand abrasion much better than any other system, therefore, should be considered in areas with high demands. Polyurea can be applied fast, hence speeding up the project, but sometimes requires specialized equipment together with trained personnel for best results, even though this might not always happen.

In conclusion, one should select a coating system based on specific project requirements, considering pipe operational requirements and surrounding conditions. Different coatings have their strengths and weaknesses, which must be evaluated carefully to determine if optimum performance is to be achieved.

Understanding Pipe Diameters and Coating Applications

Pipe coatings should always be selected with the pipe diameter in mind. This is because it directly affects the application process and appropriateness of particular types of coating materials. In some cases, smaller size diameters may only need easy accessibility for coating applications, but care should still be taken to guarantee that they are completely coated and stick. On the other hand, larger sizes require specialized spraying tools or techniques to ensure that the coat is applied uniformly in terms of thickness as well as coverage, so that there are no weak points which can corrode or cause failure. Another thing to take into account is the service conditions of piping systems since different diameters have potential impacts on flow dynamics and heat transfer, thereby affecting performances for applied coats. Consequently, both pipe dimensions and operational needs must be thoroughly evaluated to realize best practices during coating application, eventually leading to the long-term integrity of pipes.

What are the Benefits of Using Internal Pipe Coating Equipment?

Improved Pipe Longevity

The use of internal pipe coating equipment can help piping systems last longer. These coatings serve as a defense against rusting, scratching, and chemical attacks that may degrade inner surfaces. Internal liners also prevent materials from building up inside pipes, thus causing blockages that can interfere with the flow, leading to maintenance challenges, as indicated by major industry players’ findings. Smoother inside finishes result from this smoother outflow of fluids, thereby reducing energy wastage within the system while lowering wear and tear. Furthermore, modern covering technology resists high temperatures and harsh conditions, thereby lengthening the life span of tubes, besides reducing the frequency at which they should be fixed or replaced because of damage caused by these factors. Therefore, it is fair enough to say that having them done using specialized tools is being proactive about increasing their lifespan and making them work better, too.

Enhanced Flow Efficiency

Playing a major part in increasing flow efficiency within piping systems is none other than the use of equipment for coating the internal pipe. Coating the inside walls with special coatings makes them smoother, hence lowering friction and turbulence during the transportation of fluids through the pipes. Energy is lost when fluids move over a rough surface; this energy loss can be reduced where such a smooth surface exists, thus increasing flow rates and managing pressures better. Studies by professionals in this field show that if applied correctly on pipes, there will be lower head losses, which means pumps are running at their best efficiencies; also, it cuts down operational costs related to power consumption while pumping liquids from one point to another. Additionally, these coatings protect against sedimentation or any other form of fouling, therefore keeping channels clear and reducing the frequency of maintenance shutdowns required for cleaning them up again. Consequently, failure to use interior linings would compromise reliability because they ensure consistent performance along fluid transport systems.

Cost Savings and Maintenance Reduction

Not only does using internal pipe coatings lead to operational inefficiency, but it also saves a lot of money and reduces maintenance needs. Coatings prevent corrosion and degradation – the main causes of pipe failures that need costly repairs or result in entity downtime. According to industry studies, establishments can lower their upkeep costs by half if they utilize high-performance coatings since these significantly lengthen the life of piping systems. Additionally, such coatings do away with frequent cleaning and fixing prompted by sedimentation and biofilm buildup, reducing labor and material expenses used for maintenance activities. Therefore, investing in good quality interior coats is an economic profit plus a strategic move towards increasing the lifespan of pipe networks.

How do you maintain and troubleshoot internal pipe coating equipment?

Regular Maintenance Tips for Coating Equipment

It is important to follow a detailed maintenance program that involves inspecting the blast and other operational parameters to ensure that the internal pipe coating equipment will last long and work efficiently. Below are some of the key practices based on industry best practices:

- Frequent checks: Regularly carry out visual examinations to identify any signs of wear, damage, or malfunction in the system. This should include testing for leaks or blockages in hoses, pumps, and nozzles.

- Cleanliness: Keep a clean working environment around the coating equipment. Clean all surfaces of the equipment as well as storage areas regularly so as to avoid contamination, which can affect the performance of coatings.

- Calibration: Calibrate equipment periodically to ensure it operates within the manufacturer’s specified parameters. During this process, check pressure gauges and flow meters for accuracy.

- Lubrication: Apply recommended lubricants on moving parts according to what has been stated by the manufacturer to reduce friction and wear. Failure to carry out this stage may result in mechanical breakdowns due to rough operation, among other things.

- Component Replacement: Timely replace consumable components such as filters or seals lest they fail, causing expensive downtime or poor-quality finishes.

- Operator Training: Train operators continuously until they become conversant with maintenance procedures, besides know how coating materials should be handled carefully. Management 101 Awareness. A knowledgeable operator can greatly minimize the chances of equipment misuse occurring.

Incorporating these maintenance hints enables establishments to improve their internal pipe coating equipment reliability while guaranteeing peak performance and lowering costly repairs or service interruptions.

Common Problems and Solutions

- Clogging: Clogs can occur in hoses or nozzles because of trash buildup or mixing the wrong materials. Solution: You should check all passages and filters regularly and clean them as needed, also ensure that prepping and straining are done right so that nothing blocks.

- Inconsistent Coating Thickness: Equipment failures or operator errors might cause differences in thickness. Solution: Ensure flow meters are calibrated correctly, along with pressure gauges, then train operators well on application techniques for material flow to remain constant.

- Material Contamination: Coatings become compromised when impurities find their way into them, thereby leading to adhesion failure. Solution: Always keep working areas extremely clean and inspect every item used during work, especially those requested by clients, lest they contain contaminants.

- Equipment Wear and Tear: Mechanical parts wear out over time, resulting in decreased efficiency. Solution: Stick to planned servicing procedures as well as timely replacement of worn-out components, which will help combat wear, thus increasing the equipment’s lifespan.

- Operator Errors: Unskilled staff can mishandle machinery, or beginners may be experienced by beginners. Solution: Have training schemes that cover all aspects, including safety measures during the operation of coating machines.

When to Contact Us for Professional Help

There are many reasons why you should contact us for help. If you have problems that don’t seem to go away no matter what you do, we can assist. For instance, if your bathtub keeps getting blocked or the thickness of the coating on your walls is always uneven, it is important to hire professionals because they know best. Another situation where this would be necessary is when machines start showing signs like making strange sounds while running or a sudden decrease in their efficiency levels; these need immediate attention lest they break completely. Operator training may not necessarily solve everything, especially if there are no changes in application methods; thus, our courses are designed specifically for such cases, which will help save time and money, too. Also, anytime one wants a full inspection done or is thinking about upgrading their coat systems, it is good to get in touch with us since we offer great advice tailored just for you

What are the Best Practices for Applying Internal Pipe Coating?

Preparation and Cleaning of Pipe Surfaces

For inner coatings to stick well and perform best, one must prepare and clean pipe exteriors correctly. This process starts with a careful check for faults or contaminants on surfaces. It is advisable to mechanically clean pipes next by either sandblasting them, using power tools such as grinders, which can remove rust, scale, and previous coats of paint, or washing them at high pressure to get rid of oils, dirt, and other debris. Also, ensure that after cleaning, the surface becomes dry and utterly devoid of any moisture, since this could hinder the adhesion of coatings when left behind as residual water in contact with it. Finally, applying an appropriate primer might improve coating materials’ bonding abilities while ensuring their longevity and efficiency during application. Following these instructions greatly enhances internal pipe coating integrity; hence, customer satisfaction will be achieved.

Choosing the Right Type of Coating Material

To ensure they last long and perform well under operational conditions, choosing the right material for coating internal pipes is important. This means that aspects such as temperature, pressure, and chemical composition of conveyed fluids must be considered. Some common examples include epoxy-based paints, polyurethane coatings, or phenolic resins – all having individual properties suitable for certain environments. For example, adhesiveness plus resistance against moisture & chemicals are among the outstanding features possessed by epoxy types, thus making them usable almost everywhere. Conversely, in situations where there is lots of stress, flexibility and durability become paramount; hence, polyurethanes would be more appropriate in this case, too. Still, we have curing times, methods of application, and environmental rules that should aid someone during the selection process, on top of everything else that has been said before about choosing what materials can be used to coat pipes internally. Ultimately, you need a comprehensive understanding of where you expect these things to work best, followed by consultations with experts who specifically deal with coatings for pipes inside structures.

Application Techniques for Even Coating

To achieve a smooth coating on the inside pipes, specific application methods should be used depending on the coating material being used. Among the most effective ways is through airless spraying because it distributes paint evenly, minimizing running and dripping. It is important to have the right atomization and coverage by ensuring proper spray pressure as well as nozzle sizes. On the other hand, if working with smaller areas or making touch-ups, one can apply brushes or rollers since they offer more control. This means that thin layers must be applied with each coat, allowing enough time to dry failure, which may result in paint sagging or pooling. In addition, uniformity can also be improved by using an even method, such as applying in a pattern (either vertical or horizontal). Therefore, while applying paint throughout the process, regular checks ought to be done so that any defects are detected earlier, thereby giving a professional finish.